Slot Cutter Vs End Mill

Slot Cutter Vs End Mill 3,9/5 1871 votes

Slot Cutter Vs End Mill Blade

jmarkwolf

Active User

- Joined

- Nov 9, 2012

- Messages

- 459

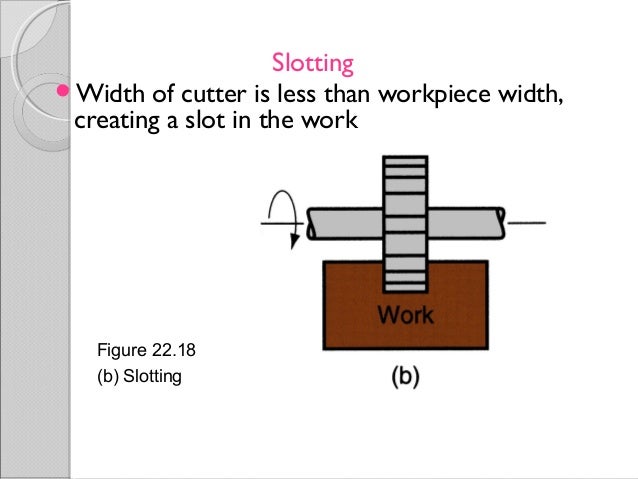

I've read on this forum about the difference between End Mills and Slot Drills and I thought I mostly understood it. Slot drills have 2 flutes, and are used for cutting slots. And equally importantly, the cutting edges on the end of the mill extend clear to the center of the bit, allowing it to do a plunge cut. The cutter diameter is the dimension that will define the width of a slot, formed by the cutting edges of the tool as it rotates. Selecting a cutter diameter that is the wrong size – either too large or small – can lead to the job not being completed successfully or a final part not being to specifications. When slotting, the feature is very close to the cutter’s diameter in size. We can’t take a 1/2″ endmill and use it to make a 1/4″ slot. In general, we want to use the largest diameter endmill that fits the feature, and then we pretty much have to make at least one cut that is full width. A two flute slot drill will, a four flute end mill cuts oversize, a three flute centre cutting slot drill/end mill (as popularised by the Clarkson FC3 'throwaway' cutters) should cut to size and a five flute cutter might. Essentially cutting a slot true to size requires balanced cutting loads.

Slot Cutter Vs End Mill Holder

Much of my home-shop machining experience has been aluminum (experimental aircraft applications). I'm advancing into the 'hard stuff' now (mild steel).

I never paid much attention to how many flutes my end mills had, I just purchased what the local Production Tool Supply had on hand. The aluminum didn't seem to care.

I recently needed to cut a 1 -1/16in diameter counter bore 0.125in deep in some angle iron, to accommodate flush mounting some weld studs I fabricated. The only end mill I had was a 2-flute.

It did the job for me, but it 'chattered' to beat the band, even with flooding with oil. It seemed to like a faster feed rate as well.

Can anyone advise 'when and why' to use end mills with various numbers of flutes?

I never paid much attention to how many flutes my end mills had, I just purchased what the local Production Tool Supply had on hand. The aluminum didn't seem to care.

I recently needed to cut a 1 -1/16in diameter counter bore 0.125in deep in some angle iron, to accommodate flush mounting some weld studs I fabricated. The only end mill I had was a 2-flute.

It did the job for me, but it 'chattered' to beat the band, even with flooding with oil. It seemed to like a faster feed rate as well.

Can anyone advise 'when and why' to use end mills with various numbers of flutes?

Slot Cutter Vs End Mill Machine

A slot drill is just a 2-flute end mill used for cutting a slot, as per the name, more clearance for the chips to come out of the back without clogging then, there'll be one flute cuts over centre so it can be used to plunge cut small distances too, to start slots in the middle of material.